A regular at the Laser Masters worlds and championships across Europe, Max Hunt runs Southeast Sailboats – a small business that provides custom made rigging solutions - www.southeastsailboats.co.uk

A look around the dinghy park at a major Laser event shows there is no right way to rig your control lines. Much of how we rig our Laser is down to what we are comfortable with, maybe we just haven’t changed what seems to work, or perhaps we don’t think that good rigging matters. Having good controls is important as it takes one more variable out of your racing: they are strong and well built, they allow you to trim your sail correctly even when you are tired, they are always rigged the same – all of which provide psychological and mechanical advantages.

No matter how you rig your Laser, in a world of marginal gains, good rigging can make a difference by reducing risk of failure, maximizing ease of use and consistency.

What can be done? Your rigging should be easy to fit in the same way from event to event so that nothing changes and your calibration remain consistent. It should also be secure – barely a major event goes by without seeing someone suffer rigging failure.

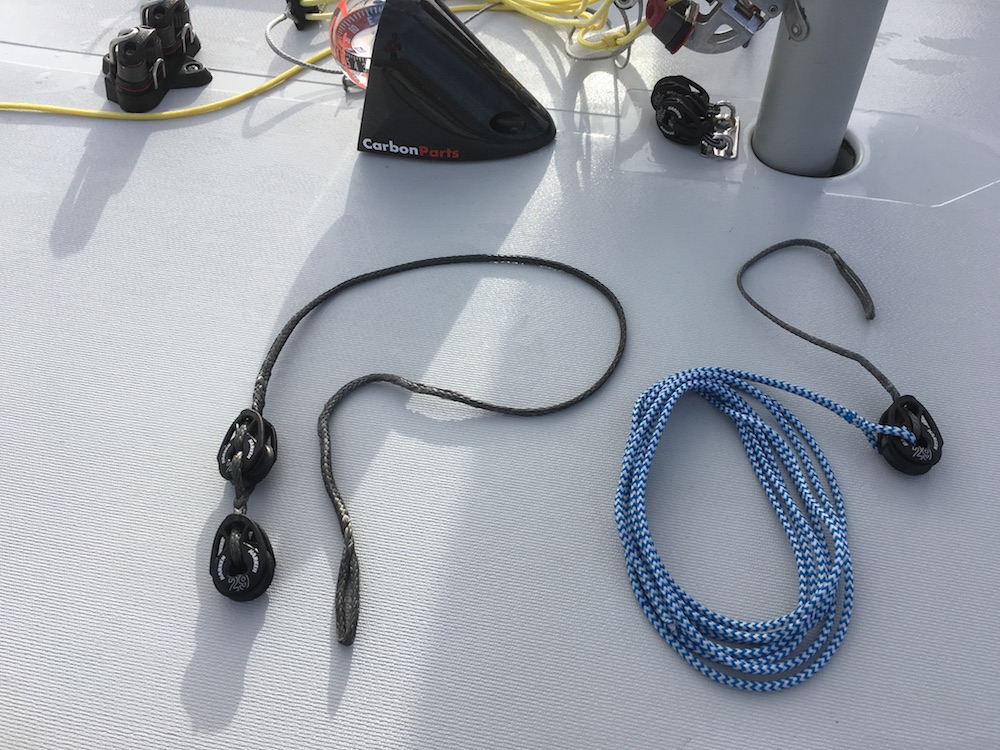

Avoiding tying and untying knots is one way of achieving these first two objectives. Having some of your lines and blocks spliced, providing it is done properly, can give you both consistency and increased security. The latest generation of blocks is designed to be ‘soft attached’ using Dyneema® or similar line but tying them on incorrectly can result in the block being pulled apart at the head. A good solution is to Brummel (lock) to splice them in the right position in the first place.

Also, for example at the clew, instead of tying on blocks, small Dyneema loops can be used as a more secure alternative, whether you prefer a shackle, hook or a block attached to the clew.

Simple and secure – Dyneema loops are an effective solution to attaching a 29mm Carbo Block to your clew shackle or hook. Smaller blocks such as Ronstan’s 20mm Orbit block used with a spliced loop can be threaded through the clew and back through the loop.

A third objective is to ensure our systems are easy to use by making them more effective and efficient by choosing the right blocks, ropes, and considering more purchases. Increasing purchase is most appropriate for the cunningham when using the new heavier MKII standard sail, and as the range of travel on the new sail is smaller, it reduces the 8:1 downside of more rope in the cockpit.

When considering block types, larger sheave sizes up to the maximum 30mm allowed under class rules, increase efficiency due to their reduced rolling resistance, and these can make a real difference particularly on the highly loaded cunningham. Here, blocks such as Harken’s 29mm T2 Soft-Attach Carbo blocks are ideal.

Effective, efficient systems reduce the effort you need to put into changing your settings, making accurate adjustments faster and easier, especially when you are tired.

Simple and secure – Dyneema loops are an effective solution to attaching a 29mm Carbo Block to your clew shackle or hook. Smaller blocks such as Ronstan’s 20mm Orbit block used with a spliced loop can be threaded through the clew and back through the loop.

When it comes to rope types much is down to personal preference or maybe it was just what was available at the time. There are a lot of performance criteria in rope selection but for control lines on the Laser, the most important is minimal stretch under load so that settings remain unchanged, whilst being strong, low in friction and friendly on the hands.

Slippery Dyneema® SK78 D12 is the default choice for primary lines. The cunningham primary must do a 180 through the tack cringle/grommet and minimizing friction is important as pulling the cunningham on is hard enough. The cunningham primary line diameter is a compromise between having a thin line that risks getting trapped in the gooseneck, or thicker line and greater friction. The outhaul primary also has to do a 180 through the boom end eye but with a lighter load than the cunningham and a larger bend radius.

Whereas primary lines should be slippery, our secondary lines should be ‘hands friendly’ both in terms of diameter and grip. Polyester / Technora® covered and/or Dyneema® cored 4mm line is the default here although some sailors are using naked 4mm D12 SK78. Good color usage on secondary lines is vital, ensuring that you can quickly distinguish and instantly grab the correct control line. Rope lengths should also be set ‘just right’ to minimize excess line in the cockpit, and so you can use the handle to maximum effect.

With everything set up perfectly you can minimize mistakes and tangles and maximize the consistency, effectiveness and security of your controls.

Finally, little things like frayed rope end, outer covers that are separating from their cores, knots to try and tie in a consistent place can result in lost time rigging, or more worryingly frustration, when we should be concentrating on what is important. Having all our rigging clean with spliced lines, and properly stitched or sealed rope ends can help eliminate this potential source of psychological disadvantage.

Southeast Sailboats fully spliced 8:1 cunningham is specially designed for the new MKII standard sail. The lower block assembly is passed through the loop on the primary and then under the kicker tang to fix it all in place. No knots to tie or come undone, no shackles or pins to undo. Effective, efficient, consistent, secure.

In competitive situations where marginal gains are important, just like having straight spars, aligned foils, a polished hull, and a good sail having a well-rigged Laser mean that you haven’t let that element to chance.

Be sure to check out Southeast Sailboats!