As the Laser’s rigging evolved and sailors’ techniques got better, the sailors get fitter and heavier, stronger sails are built and low stretch line is used, more and more load is being put onto your Laser spars. Repair laser spars is quite important to safe a life.

Typical corrosion shown at the mast fitting. Photo: 100races.blogspot.com/

Maintaining your spars correctly will ensure longevity, and knowing how to repair them and having the tools and parts on hand will allow you to miss as little sailing as possible.

One of the most important things to remember about taking care of your spars is that most of the load bearing fittings are stainless steel and the tubes are aluminum. Once you add salt water to those dissimilar metals, galvanic corrosion occurs. Since aluminum is more reactive than stainless, the mast tube around the stainless rivets will begin to corrode and weaken. This leads to the tube weakening and either the fittings pulling out or the tube breaking. Once the holes are corroded becomes very hard to keep up with.

The best practice is to repair laser spars with fresh water every time you sail in salt water. Make sure to pay special attention to all the fittings, and to especially rinse out the inside of the bottom section by filling it with water, placing your hand on the open end of the tube and moving the water around the inside of the mast. While doing so, take a close look at your rivets and fittings. If you start seeing white crust, spiderweb cracks, discolouration and movement, it is important to monitor it and consider replacing your rivets with some anti-corrosion paste as soon as possible to try to slow down the process.

Though we haven’t had to repair rivets on carbon spars, galvanic corrosion can occur with carbon as well, so we’ll have to see how the spars handle it.

When it comes time to repair laser spars, like a loose rivet or you observe corrosion starting to develop, having a few tools on hand and some knowledge can go a long way and allow you to sail more and prolong the life of your spars.

Tools needed for your spar repair kit:

First, identify what type of rivet you need based on the fitting. All the plastic fittings can use cheaper and easier to use aluminum rivets. The other advantage here is that there is no risk of corrosion by mixing aluminum, plastic and more aluminum. If the fitting is metal, like your goose neck or a metal eye strap, a stainless steel rivet is necessary. All rivets on the Laser spars are 3/16“ x 1/2" inch for maximum hold.

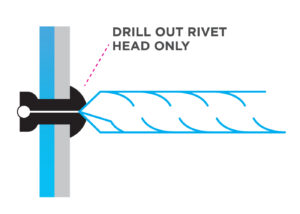

To remove an old or damaged rivet, first try to drill it out by pointing your drill directly vertically into the head. Aluminum rivets are much softer and easier to remove than stainless rivets. Your goal is to remove the head only, or at least loosen it from the rivet body. After that, you want to remove the head either by picking it in the centre and lifting it off or prying it up with a flathead screwdriver. Sometimes you can also slide the flathead screwdriver under the head and chisel the head off with a hammer.

Once your rivet is out, inspect the fitting and the mast. Give the area a good wipe down with alcohol or acetone and insert your new rivet covered liberally in Lanacote or another anti-corrosion paste or grease.

Once your rivet is out, inspect the fitting and the mast. Give the area a good wipe down with alcohol or acetone and insert your new rivet covered liberally in Lanacote or another anti-corrosion paste or grease.

Be sure to use an accordion rivet gun to make the stainless riveting easy and to drain the used rivet bits out of your spar when possible.